增透膜

This is Section 4.3 of the Laser Optics Resource Guide.

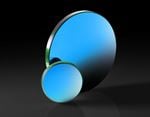

Edmund Optics offers all TECHSPEC® transmissive optics with a variety of anti-reflection (AR) coating options that vastly improve the efficiency of the optic by increasing transmission, enhancing contrast, and eliminating ghost images. Most AR coatings are also very durable, with resistance to both physical and environmental damage. For these reasons, the vast majority of transmissive optics include some form of anti-reflection coating. When specifying an AR coating to suit your specific application, you must first be fully aware of the full spectral range of your system. While an AR coating can significantly improve the performance of an optical system, using the coating at wavelengths outside the design wavelength range could potentially decrease the performance of the system.

为什么选择增透膜?

Due to Fresnel reflection, as light passes from air through an uncoated glass substrate approximately 4% of the light will be reflected at each interface. This results in a total transmission of only 92% of the incident light, which can be extremely detrimental in many applications(图 1)。过量的反射激光会降低通量,并可能导致激光诱导损伤。增透 (AR) 膜应用于光学表面,以提高系统的通量,并减少反射在系统中向后传播并产生鬼影所造成的危害。AR 镀膜对包含多个透射光学元件的系统尤为重要。许多低光系统采用增透膜光学,以便有效地利用光线。

图 1: 菲涅耳反射发生在每个材料界面。每次反射光线到达另外一个界面时,都有一部分会经历额外的菲涅耳反射1

AR 镀膜的设计使相对相移在光束反射在薄膜上、下边界 180 度之间。两个反射光束之间发生破坏性干涉,它会在两个光束离开表面之前抵消它们(图 2)。光学镀膜的光学厚度必须是 λ/4 的奇数倍数,其中,λ 是设计波长或峰值性能的优化波长,以实现反射光束之间 λ/2波长所需的路径差异。实现该差异后,将导致光束的抵消。利用入射介质 (n0) 和基片 (ns) 的折射率可以找到完全抵消反射光束所需的薄膜 (nf) 的折射率。

图 2: 每个镀膜层的折射率和厚度都经过严格的控制,以使每个反射光束之间产生破坏性干涉

V型增透膜是一种 AR 镀膜,其设计目的是增加在特定设计波长 (DWL)下的窄波段的透射率。这种镀膜类型被称为“V 形镀膜”,因为透射与波长之间的曲线形成一个“V”形,最小值为 DWL。使用单频窄带线宽激光器或窄半峰全宽 (FWHM) 光源时,V 形镀膜是获得最大透射率的理想材料1。V 形镀膜在 DWL 下的反射率通常小于 0.25%。但是,镀膜局部的反射曲线近似抛物线形状,在DWL 之外的波长下反射率明显较高(图 3)。

图 3: 使 266nm 处获得最大透射率的激光 V 型镀膜示例

表 1 显示了爱特蒙特光学标准激光 V 形镀膜的反射率和保证激光诱导损伤阈值 (LIDT)。

表 1: 爱特蒙特光学标准激光 V 型镀膜的反射率规格和保证激光诱导损伤阈值 - 可根据要求定制波长

由于反射率随光源波长远离 DWL 而迅速增加,因此带有 V 形镀膜的光学元件用于恰好或非常接近镀膜预计 DWL 的位置。V 型镀膜的一个有趣的特征是,其传输曲线的形状为半周期,因此反射率在 DWL(例如 λ0/2 或 λ0/4)的谐波下达到局部最低值,不像在 DWL 下一样能获得最优反射率。V 型镀膜通常只包含两层镀膜。简单的 V 型镀膜可以包含一个厚度为 λ/4 的层,但可能需要更多层来调整带宽,或者如果具有适当折射率的镀膜材料不可用。多层镀膜也可以补偿不同的入射角,但他们更加复杂,而且往往有更大的带宽。如果 V 型镀膜层的厚度不正确,镀膜的反射率会增加,而且 DWL 会发生变化。爱特蒙特光学的 V 型镀膜通常能使最小反射率显著低于 0.25%,但所有标准 V 型镀膜在 DWL 下的指定反射率都小于 0.25%。这允许 DWL与镀膜公差有细微的变化。

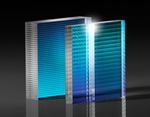

Broadband anti-reflection (BBAR) coatings are designed to improve transmission over a much wider waveband. They are commonly used with broad spectrum light sources and lasers with multiple-harmonic generation. BBAR coatings typically do not achieve transmission values quite as high as V-coats, but are more versatile because of their wider transmission band. 除了应用于包括透镜和窗镜在内的透射光学元件外,AR 镀膜也用于激光晶体和非线性晶体,以减少反射,因为菲涅耳反射发生在空气和晶体交汇处。1

增透膜选项

Edmund Optics offers all TECHSPEC® lenses with an optional single-layer, dielectric anti-reflection (AR) coating to reduce surface reflections. In addition, custom single-layer, multi-layer, V, and 2V coatings are available for both our off-the-shelf and large volume custom orders. View Custom Optical Lens Coatings for information.

图 4: Wavelength selection chart

λ/4 MgF2: The simplest AR coating used is λ/4 MgF2 centered at 550nm (with an index of refraction of 1.38 at 550nm). MgF2 coating is ideal for broadband use though it gives varied results depending upon the glass type involved.

VIS 0° and VIS 45°: VIS 0° (for 0° angle of incidence) and VIS 45° (for 45° angle of incidence) provide optimized transmission for 425 – 675nm, reducing average reflection to 0.4% and 0.75% respectively. VIS 0° AR coating is preferred over MgF2 for visible applications.

VIS-NIR: Our visible/near-infrared broadband anti-reflection coating is specially optimized to yield maximum transmission (>99%) in the near infrared.

Telecom-NIR: Our telecom/near-infrared is a specialized broadband AR coatings for popular telecommunications wavelengths from 1200 – 1600nm.

UV-AR and UV-VIS: Ultraviolet coatings are applied to our UV fused silica lenses and UV fused silica windows to increase their coating performance in the ultraviolet region.

NIR I and NIR II: Our near-infrared I and near-infrared II broadband AR coatings offer exceptional performance in near-infrared wavelengths of common fiber optics, laser diode modules and LED lights.

图 5, 图 6,和表 2 显示爱特蒙特光学的标准BBAR 镀膜选项。

图 5: 爱特蒙特光学的可见光谱标准 AR 镀膜

图 6: EO’s standard AR coatings for the near infrared (NIR) spectrum

图 7: EO 的红外 (IR) 光谱标准增透膜

表 2: 爱特蒙特光学标准 BBAR 镀膜的反射率规格

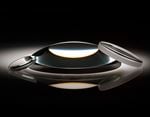

Anti-reflection coatings are available on the following TECHSPEC® Optics

参考文献

- Paschotta, Rüdiger. Encyclopedia of Laser Physics and Technology, RP Photonics, October 2017, www.rp-photonics.com/encyclopedia.html

上个章节

上个章节

或查看各区域电话

报价工具

只需输入商品编号

Copyright 2023, 爱特蒙特光学(深圳)有限公司。— 广东省深圳市龙华工业东路利金城科技工业园3栋5楼 518109 - 粤ICP备2021068591号